In modern industrial settings, electrical reliability is crucial. Robust wiring systems and well-structured signal wire bundles are the backbone of high-performance machinery and automation systems. This article explores how these wiring strategies improv

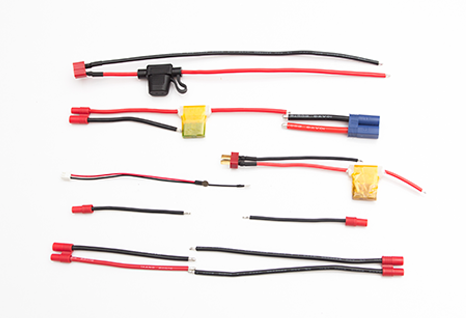

A robust wiring system refers to a setup engineered to endure environmental stress, electrical load, and long-term usage:

High-Quality Insulation: Protects against heat, oil, moisture, and abrasion.

Redundant Paths: In critical systems, alternate routing ensures continued operation if one line fails.

Heavy-Duty Connectors: Withstand vibration, mechanical stress, and multiple connection cycles.

These features are essential for sectors such as transportation, robotics, and heavy machinery.

2. The Role of Signal Wire Bundles

Signal wire bundles are groupings of wires responsible for transmitting low-voltage control signals, crucial for:

Sensor Data: Transmitting precise information from temperature, motion, or proximity sensors.

Control Commands: Carrying logic from PLCs (Programmable Logic Controllers) to actuators.

Feedback Loops: Ensuring systems operate within safe and optimal conditions.

Signal wires are typically shielded to prevent electromagnetic interference (EMI), which can disrupt performance.

3. Best Practices for Wiring in Harsh Environments

Twisted Pair Configuration: Minimizes crosstalk between signal wires.

Shielding and Grounding: Reduces EMI and ensures signal integrity.

Color Coding and Labeling: Speeds up maintenance and error detection.

4. Integrated System Advantages

Robust wiring systems and signal bundles are often part of larger industrial automation harnesses, bringing benefits such as:

Reduced Downtime: Quick diagnostics and modular replacements.

Scalability: Easy integration of new components or upgrades.

Efficiency: Organized layouts reduce airflow obstruction and simplify cable management.

1. What Makes a Wiring System "Robust"?

A robust wiring system refers to a setup engineered to endure environmental stress, electrical load, and long-term usage:

High-Quality Insulation: Protects against heat, oil, moisture, and abrasion.

Redundant Paths: In critical systems, alternate routing ensures continued operation if one line fails.

Heavy-Duty Connectors: Withstand vibration, mechanical stress, and multiple connection cycles.

These features are essential for sectors such as transportation, robotics, and heavy machinery.

2. The Role of Signal Wire Bundles

Signal wire bundles are groupings of wires responsible for transmitting low-voltage control signals, crucial for:

Sensor Data: Transmitting precise information from temperature, motion, or proximity sensors.

Control Commands: Carrying logic from PLCs (Programmable Logic Controllers) to actuators.

Feedback Loops: Ensuring systems operate within safe and optimal conditions.

Signal wires are typically shielded to prevent electromagnetic interference (EMI), which can disrupt performance.

3. Best Practices for Wiring in Harsh Environments

Twisted Pair Configuration: Minimizes crosstalk between signal wires.

Shielding and Grounding: Reduces EMI and ensures signal integrity.

Color Coding and Labeling: Speeds up maintenance and error detection.

4. Integrated System Advantages

Robust wiring systems and signal bundles are often part of larger industrial automation harnesses, bringing benefits such as:

Reduced Downtime: Quick diagnostics and modular replacements.

Scalability: Easy integration of new components or upgrades.

Efficiency: Organized layouts reduce airflow obstruction and simplify cable management.

Tel: +86-13712235188 +86-13728244346

Address:101, Building 2, No. 281, Houjie Section, Guantai Road, Houjie Town, Dongguan, Guangdong, China