In the realm of advanced manufacturing and industrial automation, custom wire harnesses are essential for ensuring efficiency, reliability, and scalability. This article dives into what makes a great industrial wire harness design and how customization im

Designing an effective custom wire harness starts with assessing the application:

Environment: Will the harness face high temperatures, moisture, or mechanical wear?

Space Constraints: Does the assembly require tight bends or unique routing paths?

Electrical Load: What is the expected voltage and current capacity?

These considerations determine the choice of materials, connectors, and insulation types.

2. Importance of Cable Assembly Choices

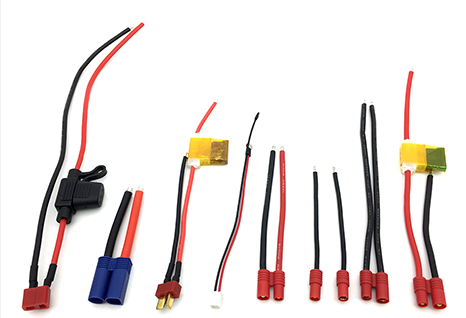

A cable assembly is more than just wires bundled together. It includes connectors, protective sleeves, and sometimes electromagnetic shielding. The choice of cable type can significantly affect:

Signal Integrity: Shielded cables reduce interference and maintain clear data transmission.

Flexibility: Flexible cables are necessary for dynamic machinery like robotic arms.

Durability: Reinforced jacketing materials ensure a longer lifespan in industrial environments.

3. Industrial Wiring Solutions for Complex Systems

Industrial environments often rely on industrial wiring solutions that integrate with automation systems. These include:

Color-coded wiring for ease of maintenance

Labeling and barcoding for inventory control

Modular harnesses that allow for quick replacements and upgrades

4. Testing and Quality Assurance

Before deployment, each wire harness undergoes rigorous testing to ensure performance:

Continuity Testing: Verifies there are no breaks or shorts.

Pull Testing: Measures the strength of connections under tension.

Environmental Testing: Simulates harsh conditions to evaluate durability.

Custom wire harnesses are indispensable in sectors like automotive, aerospace, and industrial machinery, where precision and reliability are non-negotiable.

1. Understanding the Design Process

Designing an effective custom wire harness starts with assessing the application:

Environment: Will the harness face high temperatures, moisture, or mechanical wear?

Space Constraints: Does the assembly require tight bends or unique routing paths?

Electrical Load: What is the expected voltage and current capacity?

These considerations determine the choice of materials, connectors, and insulation types.

2. Importance of Cable Assembly Choices

A cable assembly is more than just wires bundled together. It includes connectors, protective sleeves, and sometimes electromagnetic shielding. The choice of cable type can significantly affect:

Signal Integrity: Shielded cables reduce interference and maintain clear data transmission.

Flexibility: Flexible cables are necessary for dynamic machinery like robotic arms.

Durability: Reinforced jacketing materials ensure a longer lifespan in industrial environments.

3. Industrial Wiring Solutions for Complex Systems

Industrial environments often rely on industrial wiring solutions that integrate with automation systems. These include:

Color-coded wiring for ease of maintenance

Labeling and barcoding for inventory control

Modular harnesses that allow for quick replacements and upgrades

4. Testing and Quality Assurance

Before deployment, each wire harness undergoes rigorous testing to ensure performance:

Continuity Testing: Verifies there are no breaks or shorts.

Pull Testing: Measures the strength of connections under tension.

Environmental Testing: Simulates harsh conditions to evaluate durability.

Custom wire harnesses are indispensable in sectors like automotive, aerospace, and industrial machinery, where precision and reliability are non-negotiable.

Tel: +86-13712235188 +86-13728244346

Address:101, Building 2, No. 281, Houjie Section, Guantai Road, Houjie Town, Dongguan, Guangdong, China